How to: high resolution

Achieving resolving powers 1/FWHMz>50 with DMAs

-

Large trumped ratios for flow acceleration after laminarization

-

High sheath to flow ratios

-

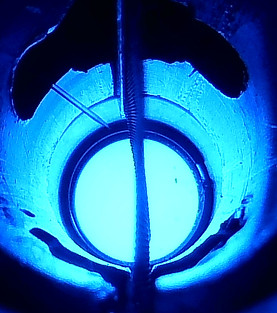

Excellent concentricity

-

Surface ultrapolishing

-

Sloped DMA channel

-

Precision latheworks

-

Stainless and PEEK on wetted parts

-

... and much more

Meet the performance team

This is our dream team of features key to achieve high resolution.

Ultrapolishing

See yourself!

Reproducibility

All conical fittings

Flow acceleration

Reynolds who?

All stainless

the rest is PEEK

Concentricity

At every corner

Bipolar electrospray

Twice the fun

The journey

NanoEngineering products stem from the inventions of the laboratory of professor Fernandez de la Mora at Yale University. It all started with a quest on reaching the best resolving powers with DMAs, but, how do you test for it? You need the best particles.

The answer came via professor Fernandez de la Mora's invention of the bipolar electrospray source, able to produce chemically defined ion clusters of ever larger size. Beyond 10nm, viral particles produce the narrowest peaks and for even larger sizes, the bipolar source can generate charge controlled analytes to extend the range. The rest is history.

The relevance of resolving power

-

It is like having glasses in a blurry world

Learn more

We are always excited to hear about your project.

Have you ever thought of tandem DMA work? We do it here.

thumbnail_edit.png)